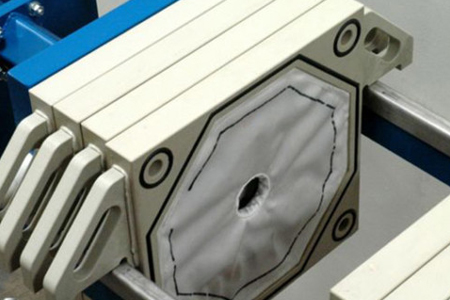

Filter cloths are adapted to the different needs of the customers, like plate dimension, cake weight, particle retention or productivity. As a result, we have developed a wide range of standard and specific designs, making up options for fixations, barrel and rubber neck, or sealing.

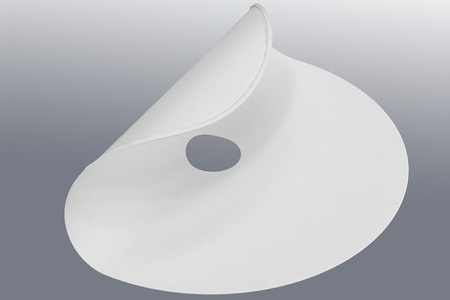

Filter discs are characterized by their precise fit and easy installation. The disc edges can be fabricated using laser cutting, hemmed or taped with optional cord. In our wide range of filter materials (polypropylene, polyester, and PTFE fabric), we can supply you with the optimal solution for your application’s chemical and thermal requirements.

The belts for continuous and discontinuous vacuum belt filters are matched to the requirements of the system, and the customer’s needs. Belts can be manufactured in various widths. As well as our innovative closure system, edge seals complete our offering to suit your application.

We have developed optimized custom solutions for fabric closure mechanisms and edgings for all types of vacuum drum filters.

Filter cloths are adapted to the different needs of the customers, like plate dimension, cake weight, particle retention or productivity. As a result, we can offer a wide range of standard and specific designs, making up options for fixations.

Our special fabric improves the degree of filtration effectiveness and enables the mechanical discharge of the solid. An even filter cake forms on the horizontal base of the filter, which ensures the best possible recovery of the solid.

The pulveriser sleeves are made out of best suitable fabric such as Woven media, cotton, polyester, Nylon etc. for various kind of operation in the filter bags. These sleeves can be made for following type of filter bags such as:

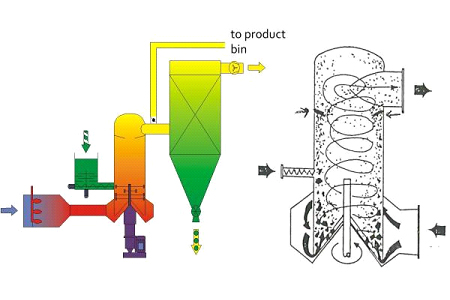

Fluidized bed drying is the optimal method for controlled, gentle and even drying of wet solids. The technology is also suitable for post-drying of spray granulated or extruded products with very low residual moisture. Our speciality fabric bags provide accurate and efficient solution which ensures the best possible recovery of the solid.

A Spint flash dryer produces powder from feed, which is viscous or gelatinous in nature, paste or filter cake. The two step process involves disintegration of the feed and drying of the disintegrated feed. Our speciality fabric bags provide accurate and efficient solution which ensures the best possible recovery of the solid.

We are equipped to meet the needs of almost all spectrums with the help of following range of materials:

The above indicated media in a wide range of applications are disposable as many of these industry cannot wash and reuse the filter media, as the finished filtrate could be contaminated with dust particles, fungus and score of other unwanted suspended matters when using washable media. In engineering industry our materials are used on Rotary Vacuum Drum filters, Coolant and Cutting Oil filters, Cold Rolling mills, Oil filtration, grinding and honing machine oil filters. We have a wide range of media for the above in chemically bonded as also in thermally bonded fibres.

Our unique filter media offer following advantages :